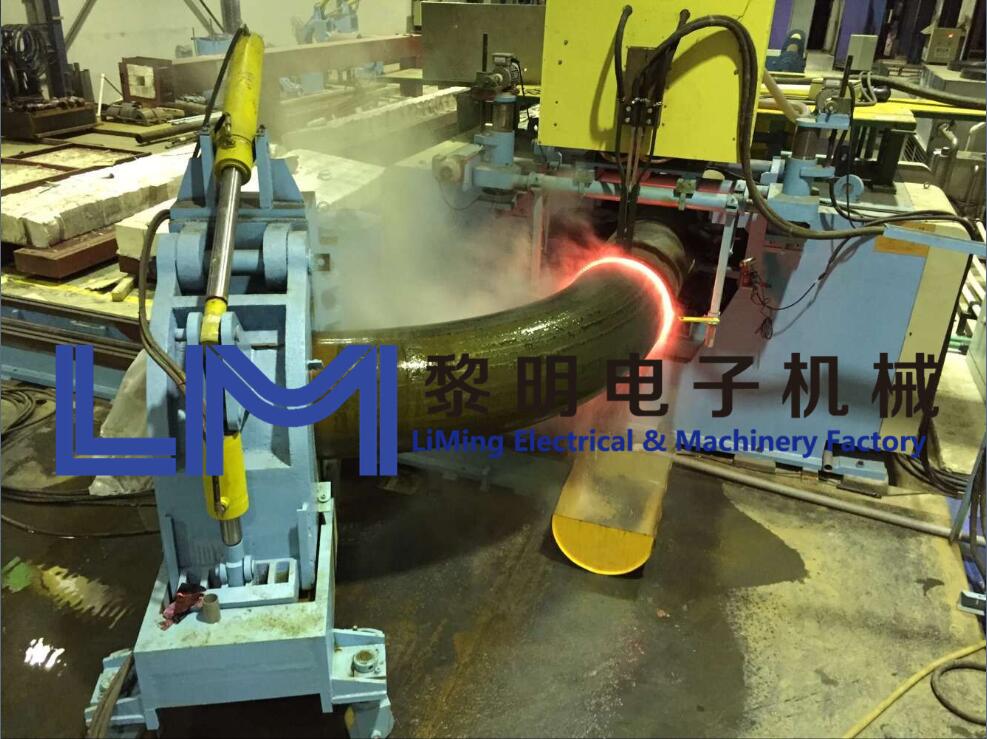

High Quality Induction Pipe Bending Machines are important parts commonly used in industrial boundaries. Generally, bending machines are used for twists and turns. The pipe bending machine can be roughly divided into a CNC pipe bending machine, a hydraulic pipe bending machine and the like. It is mainly used for electric power construction, public railway construction, pipeline installation and repair of steam boilers, bridges, boats, furniture, decoration, etc. It has the advantages of many functions, correct structure and simple operation. So how do the tube bender perform the load test? Please follow three ways:

1. Each Carbon Steel Pipe Bending Machine shall be subjected to full load test, and the pipe fittings shall be bent twice according to its large rolling torque (torsional viewing point 180°).

2. During the full load test, the automatic pipe bending machine should be stable and reliable and comply with relevant regulations.

3. For the type test of new products and new products, the overload test should be carried out. The overload test is carried out according to the automatic pipe bending machine, and the pipe fittings with a large rolling torque of 110% are bent three times (the twist point of view is 180°). The allowable sampling test for batch-type manufacturing shall be tested at 10% of the output of each batch, but not less than one.

TEL:008613931703233

Fax : 0086-317-6817833

Email:lmdzjxc@lmdzjxc.com

Address:Xiwang New District ,Mengcun Hui Autonomous County, Hebei province,China. sitemap google