What are the types of pipe bending machines? Cold Elbow Machine Exporter comes to solve your doubts. Bending Pipe Machine is a kind of widely quoted equipment. Its uses are mainly for boilers, bridges, ships, furniture, electric power construction, automobile pipeline processing construction and some repairs and so on. The pipe bending machine can be bent into various shapes, such as I-beam, channel steel, angle iron, wire, etc .; it can also be used to roll coiled tubes, "u" shaped tubes, half tubes, coiled tubes, etc.

Tube bending machines in daily life can be divided into CNC tube bending machines, hydraulic tube bending machines and other types.

The CNC Pipe Expanding Machine can be used to wind a pipe with a bending radius (single mode) or two bending radii (double mode) in the cold state. It is widely used in the bending of various pipes and wires in the automotive, air-conditioning and other industries.

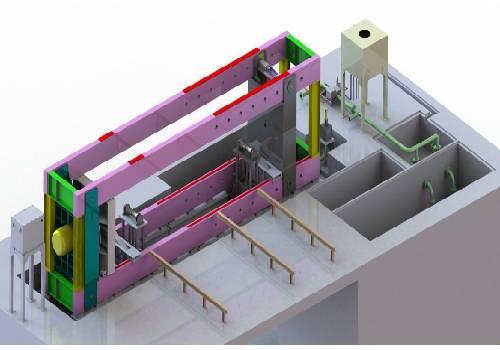

Hydro Tester Machine

Hydraulic pipe bending machine has the advantages of multiple functions, reasonable structure, simple operation, convenient movement, fast installation, etc. It is used for the laying and repair of pipelines in power construction, public railway construction, boilers, bridges, ships, furniture, decoration, etc. In addition to the pipe bending function, the pipe machine can also use the oil cylinder as a hydraulic jack. Compared with the CNC pipe bending equipment, it has the characteristics of cheap price and convenient use, and occupies the leading product position in the domestic pipe bending machine market. There are two bending methods for the pipe bending machine: cold bending, its models include hydraulic pipe bending machine, electric pipe bending machine and three-roller bending machine; hot bending, its representative model is the intermediate frequency pipe bending machine.

Among them, the hydraulic pipe bender that people often use, and all the joints of the hydraulic pump station of the hydraulic pipe bender are equipped with oil-resistant rubber sealing rings. If the sealing ring is damaged or leaks, it should be replaced in time. When cleaning the hydraulic bender oil tank, clean the oil inlet filter of each pump. If it is found that the forward and retreat are not working properly, first check whether the solenoid valve is operating. If the solenoid valve is operating normally, then check whether the sequence valve 6X3, overflow valve YF-L20H4 or one-way unloading valve 4HD3 are stuck. Within 1-2 months after the hydraulic pipe bender starts to use, clean the oil tank and filter the hydraulic tank once. Check the fasteners in all parts to make them in a tight state.

TEL:008613931703233

Fax : 0086-317-6817833

Email:lmdzjxc@lmdzjxc.com

Address:Xiwang New District ,Mengcun Hui Autonomous County, Hebei province,China. sitemap google