As a professional induction pipe bending machine manufacturer, we can tell you the work process of induction pipe bending machine.

Straight pipe is placed in the machine bed with an induction heating coil located around the pipe at one end. This heating coil creates a narrow, circumferential, heated band around the material. As the pipe reaches the required temperature, it is slowly pushed forward through the coil at a consistent speed and temperature and shaped into a bend. After the material passes through the coil, it is cooled by a controlled water cooling system.

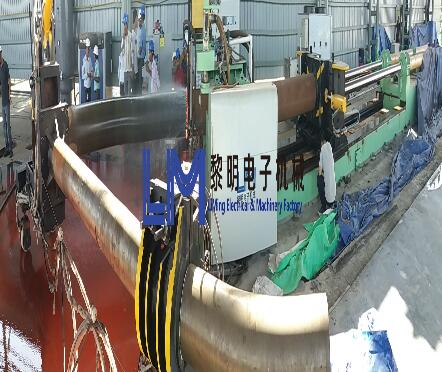

Pipes formed with Liming induction bending machine can be found in applications where little to no wall thinning and minimal ovality is mandatory. Industries requiring this critical application include: petroleum pipelines (on and offshore), processing plants, oil & gas refineries, power generation, food processing, shipbuilding yards, chemical.

TEL:008613931703233

Fax : 0086-317-6817833

Email:lmdzjxc@lmdzjxc.com

Address:Xiwang New District ,Mengcun Hui Autonomous County, Hebei province,China. sitemap google